Understanding the Importance of Moisture Content of Cereal Grains in Farming and Business Efficiency

The moisture content of cereal grains plays a pivotal role in determining the success of farming operations, storage strategies, and overall profitability in agricultural businesses. For industries involved in Farm Equipment Repair and Farming Equipment, understanding this critical factor can significantly influence maintenance routines, equipment longevity, and crop quality. This comprehensive guide explores the nuances of moisture content in cereal grains, its impact on the agri-business sector, and how advanced machinery and techniques can optimize outcomes for farmers and entrepreneurs alike.

What Is the Moisture Content of Cereal Grains?

The moisture content of cereal grains refers to the percentage of water present within the grain’s structure, typically expressed as a percentage of the grain’s total weight. This parameter is fundamental in assessing grain quality, determining appropriate harvesting times, and ensuring safe, efficient storage.

When cereal grains such as wheat, corn, barley, oats, and rice reach optimal moisture levels, they are most suitable for harvest, transportation, and storage. Excess moisture can lead to mold growth, spoilage, and pest infestation, while insufficient moisture can cause brittleness and damage during handling. Therefore, maintaining ideal moisture content is crucial for minimizing losses and maximizing the nutritional and commercial value of cereal crops.

The Significance of Moisture Content in Agricultural Business

1. Impact on Harvest Timing and Crop Quality

Determining the right time to harvest is critical in cereal grain production. Harvesting too early when moisture levels are high (above 20-25%) risks grain spoilage during storage, while saving crops too late can lead to over-drying, harvesting losses, and reduced grain quality. The moisture content of cereal grains serves as a decision-making parameter for farmers to optimize harvest timing, ensuring maximum yield and quality.

2. Influence on Storage and Preservation

Proper storage hinges on maintaining the moisture content of cereal grains within safe limits (usually around 13-15%). Excess moisture fosters fungal growth, such as *Fusarium* and *Aspergillus*, which can produce harmful mycotoxins, compromising food safety and market value. Conversely, overly dry grains are more prone to cracking, damage, and increased handling costs. Implementing precise moisture control and monitoring systems ensures grains remain safe and retain nutritional qualities over extended periods.

3. Effect on Business Profitability and Marketability

A strong understanding of moisture content of cereal grains directly correlates with higher revenues. Quality-certified grains with optimal moisture levels fetch better prices, and less spoilage reduces post-harvest losses. This knowledge allows farmers and agribusinesses to meet stringent market standards, expand export opportunities, and establish a reputation for reliable quality, ultimately fueling long-term business growth.

Measuring and Controlling Moisture Content in Cereal Grains

Types of Moisture Measurement Tools

- Moisture Meters: Hand-held or portable devices utilizing capacitance or conductance technology for rapid on-site measurements.

- Laboratory Testing: Oven-drying and Karl Fischer titration provide precise moisture analysis, suitable for quality control and certification.

- Infrared Moisture Analyzers: Advanced equipment used in commercial settings for real-time and non-destructive testing.

Best Practices for Moisture Control

- Timely Harvesting: Monitor crop moisture levels closely and plan harvests when the cereal grains reach ideal moisture content.

- Proper Drying Techniques: Use mechanical dryers, airflow systems, or natural sun drying as appropriate to reduce excess moisture efficiently.

- Optimal Storage Conditions: Maintain controlled environments with low humidity and appropriate aeration to prevent moisture reabsorption and spoilage.

- Regular Monitoring: Implement continuous moisture monitoring with advanced sensors, integrated with farm management systems for proactive decision-making.

Role of Farming Equipment in Managing Moisture Content

1. Harvesting Equipment

Modern harvesters equipped with moisture sensors can determine real-time grain moisture levels, allowing operators to make immediate decisions on harvest timing. Combining these tools with GPS and data analytics can optimize the timing across different field sections, ensuring uniform moisture levels and reducing post-harvest processing costs.

2. Grain Dryers and Storage Facilities

High-quality farming equipment, such as grain dryers, are essential for adjusting moisture levels during post-harvest processing. These systems use controlled airflow and temperature settings to achieve target moisture percentages, preventing spoilage and maintaining grain integrity. Proper storage equipment includes aerated bins, silos with humidity control, and moisture-proof infrastructure to safeguard the grain's quality over extended periods.

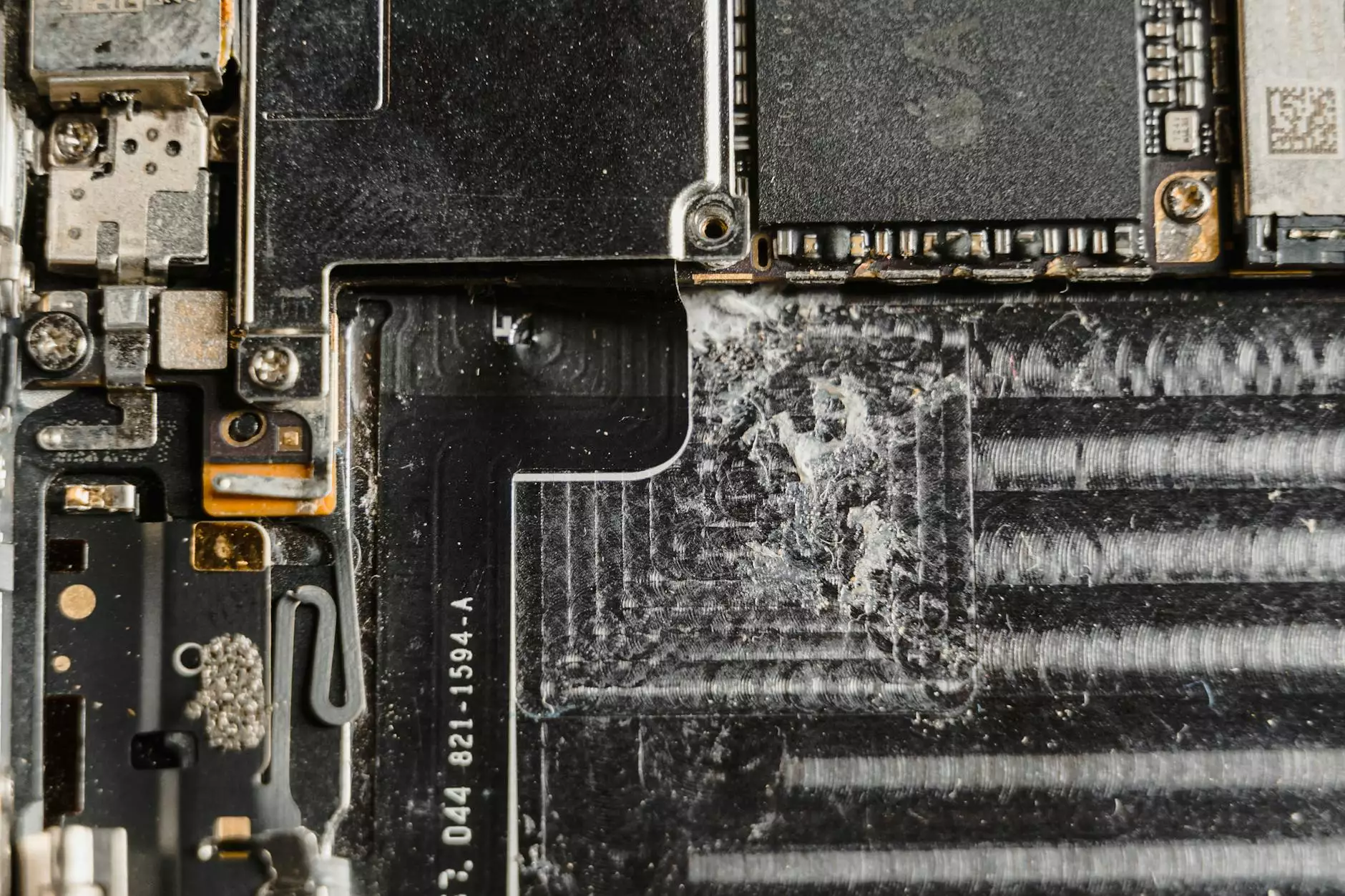

3. Maintenance and Repair of Agricultural Machinery

Reliable farm equipment performance directly affects the ability to control moisture content of cereal grains. Regular Farm Equipment Repair ensures that moisture sensors, dryers, and harvesters operate at peak efficiency, minimizing downtime and operational costs. Investing in professional repair services, like those offered by TSGC Inc., can significantly prolong equipment lifespan, ensuring consistent crop quality and business profitability.

Technological Innovations Enhancing Moisture Management

Smart Farming Technologies

The integration of IoT (Internet of Things) devices and cloud-based data analytics has revolutionized how farmers manage moisture content of cereal grains. Sensors placed within fields and storage units provide real-time data, allowing farmers to make informed decisions on harvest timing, drying processes, and storage conditions. Automation reduces human error and enhances efficiency.

Artificial Intelligence and Machine Learning

AI-driven systems analyze historical weather data, crop conditions, and moisture readings to forecast optimal harvest times and drying schedules. These predictive models help farmers minimize moisture-related risks, optimize resource use, and improve crop quality — translating into higher business margins.

Environmental Factors and Their Impact on Moisture Content

Environmental conditions such as humidity, temperature, and rainfall profoundly influence the moisture content of cereal grains. During the growing season, managing these factors through irrigation, drainage, and crop rotation helps achieve consistent moisture levels. Post-harvest, weather conditions govern the drying process, requiring adaptive strategies to prevent mold or cracking.

The Future of Moisture Management in Agriculture

As agricultural technology advances, the industry is moving toward fully automated and intelligent systems capable of maintaining optimal moisture content of cereal grains seamlessly. Future developments may include drone-based monitoring, AI-powered drying facilities, and blockchain-enabled traceability to ensure quality and transparency at every stage of the supply chain.

Conclusion: Embracing Expertise and Equipment for Optimal Business Performance

Understanding and effectively managing the moisture content of cereal grains is not merely a technical requirement but a strategic business imperative. From timely harvesting, precision drying, to sophisticated storage solutions — leveraging advanced farming equipment and expert repair services like those from TSGC Inc. — ensures that your agricultural operation remains competitive, profitable, and resilient in a rapidly evolving industry.

By prioritizing moisture management, farmers and agribusinesses can optimize crop quality, reduce losses, meet market standards, and enhance overall sustainability. Embracing innovative technologies and professional equipment repair services paves the way for a prosperous future in agriculture, aligning with best practices in Farm Equipment Repair and Farming Equipment.