Understanding Grain Drying Equipment: Essential Insights for Farmers

In the world of agriculture, grain drying equipment plays a pivotal role in ensuring the quality and longevity of harvested crops. As farmers strive for the best yield, understanding the various facets of this equipment is crucial. In this article, we will explore the types, benefits, operational aspects, and the impact of advancements in grain drying technology. We aim to provide an exhaustive resource for both seasoned farmers and newcomers to the agricultural business.

What is Grain Drying Equipment?

Grain drying equipment refers to machines designed to remove moisture from harvested grains. Moisture control is essential in preventing spoilage, mold, and insect infestations, which can drastically reduce crop value. The right drying equipment not only preserves the quality of the grain but also enhances storage capabilities.

Types of Grain Drying Equipment

There are several types of grain drying equipment available, each suited to different farming needs and scales. Here are the most common types:

- Portable Grain Dryers: These compact units are ideal for small to medium-sized farms. They can be easily moved from one location to another, allowing farmers to dry grain directly at the harvest site.

- Batch Grain Dryers: Batch dryers work by drying a specific quantity of grain at one time. They are perfect for operations where drying needs fluctuate based on harvest sizes.

- Continuous Flow Dryers: Suitable for large-scale operations, these systems allow grain to be dried continuously as it moves through the machine. This provides greater efficiency and higher output.

- Hybrid Dryers: Combining principles from both batch and continuous systems, hybrid dryers offer versatility in drying capacity and are ideal for diverse farming operations.

- Solar Grain Dryers: Utilizing renewable energy, solar dryers are an eco-friendly option for drying grains, especially in sunny regions. They reduce operational costs and minimize the carbon footprint.

The Importance of Grain Drying

Proper grain drying is significant for several reasons. Let's delve into its benefits:

Preservation of Quality

Maintaining the quality of harvested grains is essential for market competitiveness. Proper drying prevents spoilage, retains grain color and flavor, and ensures high-quality output suitable for sale.

Enhanced Storage Life

Grains stored with optimal moisture content can be kept for extended periods without degradation. This is particularly important for farmers looking to sell their products off-season for higher prices.

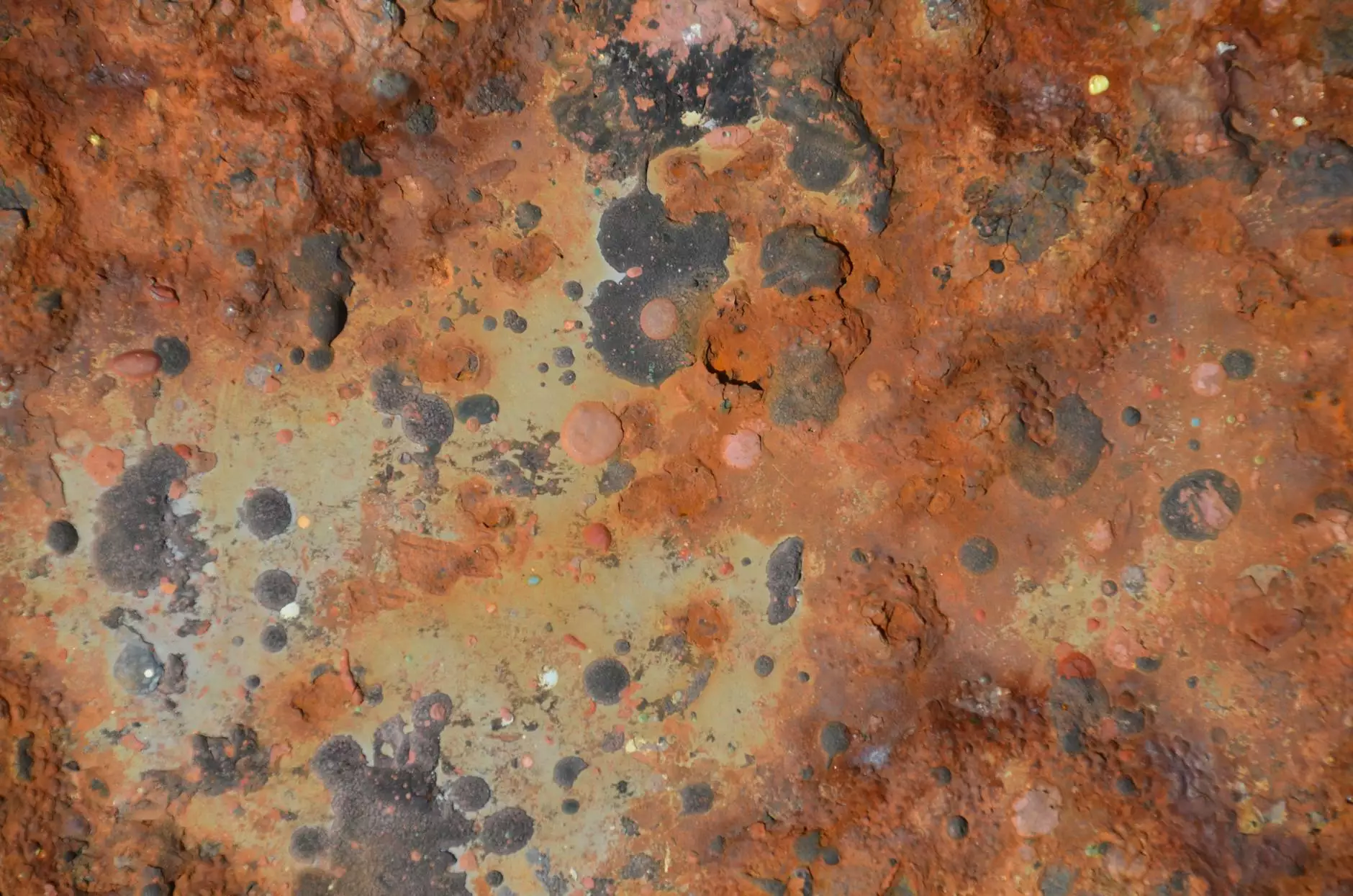

Prevention of Mold and Pest Infestation

High moisture levels can create an environment conducive to mold growth and pests. By utilizing grain drying equipment, farmers can mitigate these risks effectively.

Improved Market Value

Grain that is well-dried not only meets market standards but can also command a better price. Farmers who invest in quality drying equipment can evaluate and improve the marketability of their produce.

How Grain Drying Equipment Works

The operation of grain drying equipment generally follows these steps:

- Loading: Grains are loaded into the dryer. This process varies depending on the type of dryer being used.

- Heating: The drying system heats air to a specific temperature before it circulates through the grain, effectively reducing moisture content.

- Airflow: Proper airflow is crucial. The air must be evenly distributed to ensure that all grain receives adequate drying.

- Cooling: Once the desired moisture level is achieved, the grains are allowed to cool before being unloaded. This step helps prevent possible condensation.

- Unloading: Finally, the dried grain is unloaded and prepared for storage or market.

Choosing the Right Grain Drying Equipment

With multiple options available, selecting the right grain drying equipment can be overwhelming. Here are some factors to consider:

1. Capacity Needs

Estimate your drying capacity based on your typical harvest yield. Large farms may require continuous flow systems, while smaller farms may find batch dryers sufficient.

2. Energy Efficiency

Energy consumption is a key factor in operating costs. Look for grain dryers that offer high efficiency to reduce long-term expenses, potentially opting for solar or hybrid options.

3. Brand Reputation and Warranty

Research various manufacturers for their reliability, customer feedback, and warranty policies. Choosing a reputable brand ensures better quality and support.

4. Technology and Automation

Modern grain drying equipment often comes with automated controls. These can greatly enhance efficiency, allowing for better monitoring of moisture levels and drying conditions.

Maintenance of Grain Drying Equipment

Regular maintenance is crucial for keeping your grain drying equipment in optimal condition. Here are some valuable maintenance tips:

1. Routine Inspection

Inspect all parts of the dryer on a regular basis for wear and tear. This includes checking fans, heating elements, and moisture sensors.

2. Cleaning

Thoroughly clean the equipment after each use to prevent grain buildup and reduce the risk of mold and pest infestations.

3. Lubrication

Ensure that moving parts are properly lubricated to enhance performance and prolong equipment life.

Future Trends in Grain Drying Technology

As agricultural technology evolves, so does grain drying equipment. Here are some trends to watch for:

1. Smart Drying Solutions

Advancements in technology are leading to smart drying solutions that utilize IoT (Internet of Things) for real-time monitoring and efficiency optimization.

2. Sustainable Practices

With increased focus on sustainability, manufacturers are developing more energy-efficient dryers and eco-friendly materials, promoting green farming practices.

3. Data Analytics

The use of data analytics in farming operations allows for better decision-making regarding grain drying management, helping optimize costs and yields across the board.

Conclusion

Investing in the right grain drying equipment is essential for any farmer looking to enhance their productivity, maintain crop quality, and improve their bottom line. From understanding the various types of drying equipment to recognizing their operational importance, farmers can make informed decisions to propel their farming operations forward. With technology continuing to evolve, staying ahead of trends in grain drying will ensure long-term success in an ever-competitive agricultural landscape.

To learn more about our services, including Farm Equipment Repair and other Farming Equipment, visit us at tsgcinc.com.